Product Introduction:

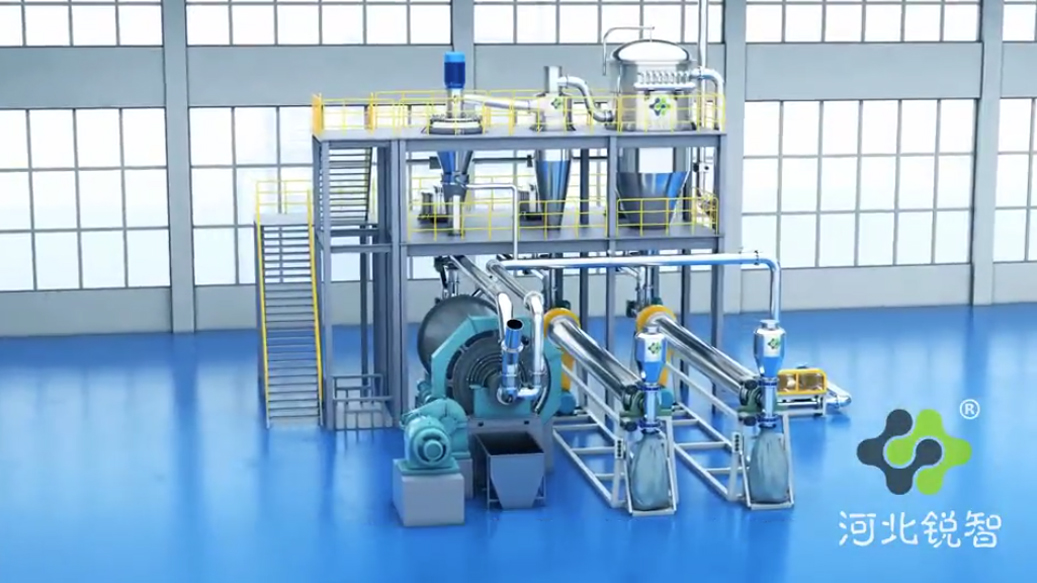

Aluminum Powder Classifier Milling system is an innovative device that integrates dry milling and dynamic classification of materials.

The system is characterized by nitrogen protection, closed-circuit circulation, and full positive pressure, which ensures safe production.

The particle size distribution of the produced powder is narrow, adjustable and controllable, enabling intelligent production.

Inlet and outlet particle size:

Feeding particle size is 10um-30um. Feeding bulk density is 0.15-2 dry material. Discharging particle size is D50=5um-100um adjustable.

Suitable products:

Flake aluminum powder、Spherical aluminum powder、Aluminum magnesium alloy powder、 Coatings

Energy Consumption Per Output

|

Name |

Model |

Installed capacity |

Feed particle size |

Discharge particle size |

24-hour production capacity |

Maximum power consumption |

|

Mixing process |

RZL-6600L |

150Kw |

1μm-200μm |

5-200μm |

5T-30T |

90Kw/h |

|

Aluminum magnesium alloy process |

RZL-6600L |

150Kw |

1-30mm |

40-160μm |

5T-30T |

90Kw/h |

|

Aluminum powder crushing process |

RZL-6600L |

150Kw |

5μm-10mm |

10-200μm |

1T-10T |

110Kw/h |

Production Process

Technical Indicators of Flake Aluminum Powder

| Item Number | Activity | Particle Size Distribution | Impurity Content | |||||||

| Particle Size/μm | Mass ≤% | Fe | Si | Cu | Mn | H2O | Grease | Cu+Zn | ||

| FLQ355A | 94 | 355 | 0.3 | 0.7 | 0.5 | —— | —— | 0.08 | 0.7 | 0.05 |

| -160 | 8 | |||||||||

| FLQ355B | 94 | 355 | 5 | 0.7 | 0.5 | — | —— | 0.08 | 1 | 1 |

| -160 | 30 | |||||||||

| FLQ250 | 94 | 250 | 0.3 | 0.7 | 0.5 | — | — | 0.08 | 0.8 | 0.05 |

| -100 | 8 | |||||||||

| FLQ224 | 92 | 224 | 0.3 | 0.8 | 0.7 | —— | —— | 0.08 | 0.9 | 0.05 |

| -80 | 10 | |||||||||

| FLQ160 | 90 | 160 | 0.3 | 1 | 0.8 | —— | —— | 0.08 | 1 | 0.05 |

| -63 | 12 | |||||||||

| FLQ80A | 82 | 80 | 1 | 0.6 | 0.6 | 0.1 | 0.01 | 0.1 | 3.8 | 0.05 |

| FLQ80B | 90 | 80 | 1.5 | —— | —— | —— | —— | —— | 3.5 | — — |

| FLQ80C | 80 | 80 | 1 | —— | —— | —— | —— | —— | 3.5 | —— |

| FLQ80D | 81 | 80 | 1 | —— | —— | —— | —— | —— | 4.5 | —— |

| FLQ80E | 85 | 80 | 1 | —— | —— | —— | —— | —— | 2.8 | —— |

| FLQ80F | 85 | 80 | 0.5 | —— | —— | —— | —— | —— | 3 | —— |

| FLQ63A | 88 | 63 | 0.3 | —— | —— | —— | —— | —— | 3.5 | —— |

| FLQ63B | 85 | 63 | 1 | —— | —— | —— | —— | —— | 3.5 | —— |

| FLQ56 | 82 | 56 | 0.3 | 0.6 | 0.6 | 0.1 | 0.1 | 0.1 | 3.8 | —— |

| FLQ45 | 80 | 45 | 0.5 | 0.6 | 0.6 | 0.1 | 0.1 | 0.1 | 3.8 | —— |

| FLQ30 | 80 | 30 | 1 | 0.6 | 0.6 | 0.1 | 0.1 | 0.1 | 4.5 | —— |

| FLQ20 | 80 | 20 | 2 | 0.6 | 0.6 | 0.1 | 0.1 | 0.1 | 4.5 | —— |

| FLQ10 | 80 | 10 | 5 | 0.6 | 0.6 | 0.1 | 0.1 | 0.1 | 5 | —— |

Technical Indicators of Aluminum-Magresium Alloy Powder

| ltem Number | Partide Size Distribution | Activity% | Aluminum Content% | Impurity Content ≤% | |||||

| Particle Szelum | Mass≤% | Al | Fe | Si | Cu | CI | H₂O | ||

| FLM1 | 700 | 0.3 | 98 | 50±3 | 0.4 | 0.2 | 0.015 | 0.02 | 0.1 |

| 630 | 8 | ||||||||

| -315 | 8 | ||||||||

| FLM2 | 450 | 0.3 | 97.5 | 50±3 | 0.4 | 0.2 | 0.015 | 0.02 | 0.1 |

| 315 | 8 | ||||||||

| -140 | 8 | ||||||||

| FLM3 | 315 | 0.3 | 97 | 50±3 | 0.5 | 0.5 | 0.015 | 0.02 | 0.1 |

| 160 | 8 | ||||||||

| -71 | 22 | ||||||||

| FLM4 | 160 | 0.3 | 96.5 | 50±3 | 0.5 | 0.7 | 0.015 | 0.02 | 0.1 |

| 80 | 8 | ||||||||

| FLMH4 | 160 | 0.3 | 90 | 50±4 | —— | —— | —— | 0.04 | 0.2 |

| 80 | 6 | ||||||||

FAQ

Q1 What qualifications and certifications does your company have?

Our company is ISO9001:2015 certified, with CE certified dust explosion-proof equipment. Some products comply with EN standards. Ruizhi is also a member of the Fire and Explosion Prevention Working Group of the National Committee for Machinery Safety Standardization.

Q2 What are the advantages of Aluminum Powder Classifier Milling System?

Our milling system features nitrogen protection, full positive pressure, dry milling and closed-loop control, offering explosion-proof safety, high efficiency, narrow particle distribution, and eco-friendly performance.

Q3 How long is the warranty period?

We provide remote support, on-site commissioning, and operator training through manuals and video tutorials.

Service Warranty

Work with Ruizhi – Global Dust Safety Partner

News Center

Hebei Ruizhi Nano technology Co., Ltd.--30 years of innovation in explosion-proof milling and dust safety equipment, trusted by industries worldwide.

Nov. 26, 2025

Hebei Ruizhi Pioneers Explosion-Proof Grinding Technology in Global Industrial Safety Field

Nov. 24, 2025

Nov. 24, 2025

About Us

With 30 years of experience and 90% market share in China’s aluminum powder explosion-proof systems, Ruizhi provides safe, certified, and efficient solutions for industries worldwide.

Navigation

Navigation

Contact Information