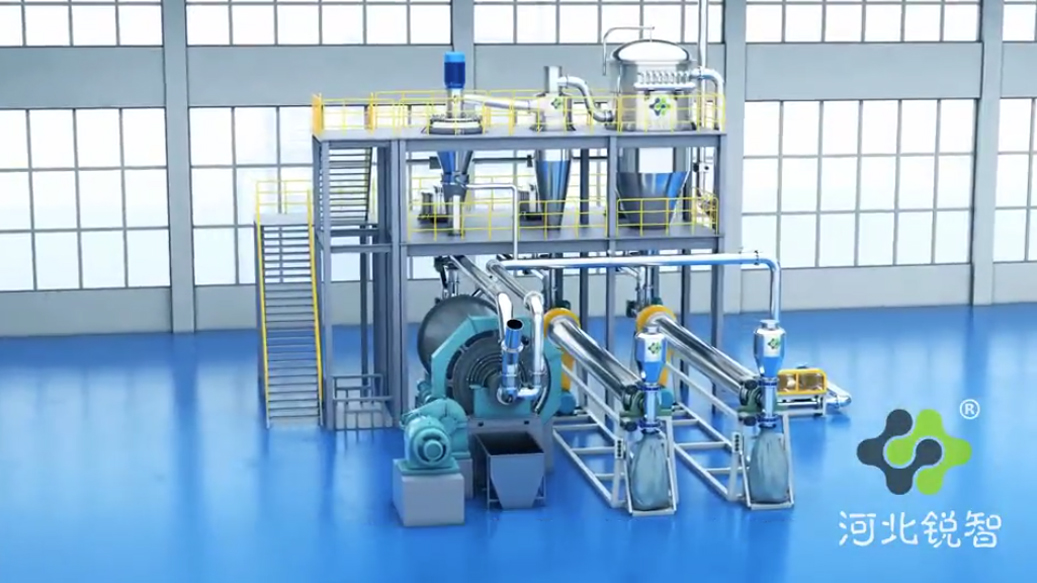

Product Introduction:

Ball mill is the key equipment for crushing materials after they are broken. The cylinder is generally made of welded steel plates, closed at both ends with end covers, and the inner wall of the cylinder is inlaid with wear-resistant lining to prevent the cylinder from wear. The cylinder is equipped with grinding bodies such as steel balls and steel segments.

Product Advantages

Technical Performance Indicators

|

Model |

Cylinder rotation speed |

Ball loading capacity |

Feed particle size |

Discharge particle size |

Motor power |

Production capacity |

Total weight |

|

Φ900*1800 |

36-38rpm |

1.5t |

≤20mm |

0.075-0.89mm |

18.5kW |

0.65-2t/hour |

5.85t |

|

Φ900*3000 |

36rpm |

2.7t |

≤20mm |

0.075-0.89mm |

22kW |

1.1-3.5t/hour |

6.98t |

|

Φ1200*2400 |

36rpm |

3t |

≤25mm |

0.075-0.6mm |

30kW |

1.5-4.8t/hour |

13.6t |

|

Φ1200*3000 |

36rpm |

3.5t |

≤25mm |

0.074-0.4mm |

37kW |

1.6-5t/hour |

14.3t |

|

Φ1500*3000 |

29.7rpm |

7.5t |

≤25mm |

0.074-0.4mm |

75kW |

2-5t/hour |

19.5t |

FAQ

Q1 What qualifications and certifications does your company have?

Our company is ISO9001:2015 certified, with CE certified dust explosion-proof equipment. Some products comply with EN standards. Ruizhi is also a member of the Fire and Explosion Prevention Working Group of the National Committee for Machinery Safety Standardization.

Q2 Is there independent intellectual property rights and third-party testing?

Yes. We own several patents in explosion-proof systems and can provide third-party test reports such as CNAS and CE.

Q3 How long is the delivery cycle?

Standard equipment delivery is 5–9 weeks. Spare parts are usually in stock for fast shipping.

Q4 How to ensure packaging and transportation?

All products are packed in moisture-proof, anti-static, shock-resistant wooden cases, suitable for sea and air shipping.

Q5 How long is the warranty period?

We provide remote support, and operator training through manuals and video tutorials.

Service Warranty

Work with Ruizhi – Global Dust Safety Partner

News Center

Hebei Ruizhi Nano technology Co., Ltd.--30 years of innovation in explosion-proof milling and dust safety equipment, trusted by industries worldwide.

Nov. 26, 2025

Hebei Ruizhi Pioneers Explosion-Proof Grinding Technology in Global Industrial Safety Field

Nov. 24, 2025

Nov. 24, 2025

About Us

With 30 years of experience and 90% market share in China’s aluminum powder explosion-proof systems, Ruizhi provides safe, certified, and efficient solutions for industries worldwide.

Navigation

Navigation

Contact Information