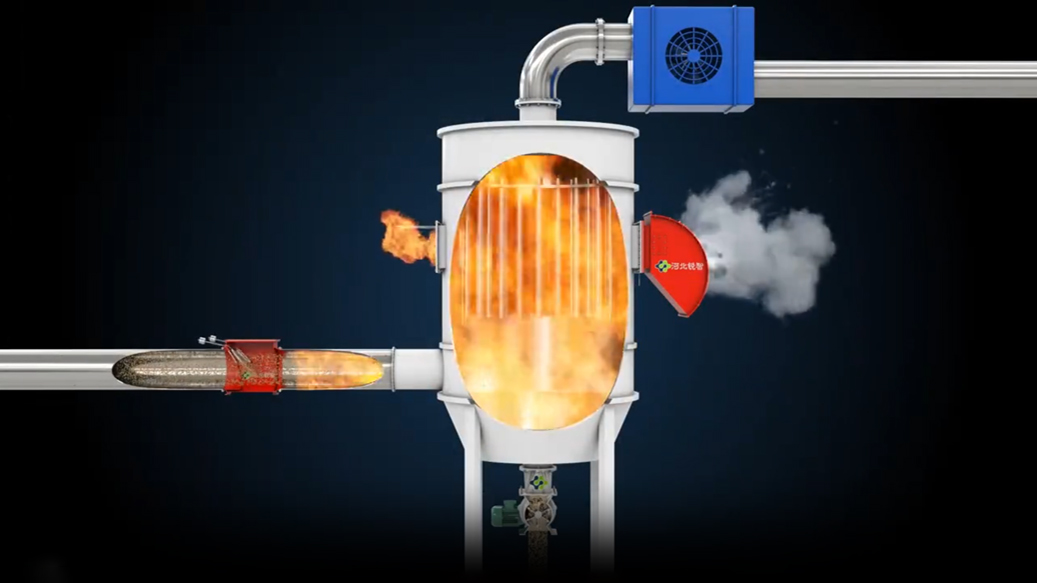

Product Introduction:

The explosion-proof flap valve is a pressure differential self-operated dust explosion isolation valve that does not require external electrical equipment. It is safe and reliable and can effectively and automatically prevent the spread of flammable dust explosions from one area to other areas, thereby eliminating the possibility of secondary explosions. The flap can be manually reset and reused

Product Advantages

Technical Performance Indicators

|

Items |

Parameters |

||

|

Size |

DN100~DN200 |

DN250~DN600 |

DN600+~DN1000 |

|

Installation distance |

2~7meters |

3~7.5meters |

DNx5~DNx10 |

|

Applicable dust |

ST1 and ST2 |

ST1 and ST2 |

ST1 |

|

Pred,max |

0.04MPa |

||

|

Minimum pressure loss |

100Pa~500Pa |

||

|

Explosion resistance |

0.082MPa |

||

|

Temperature range |

-30℃~135℃ |

||

|

Humidity range |

≤80% |

||

|

Applicable process |

Negative pressure process, oxygen content not higher than the oxygen content in the air (21%) |

||

|

Wind speed range in the duct |

0~30m/s |

||

|

Installation methods |

Horizontal installation |

||

|

Material |

Carbon steel and stainless steel |

||

|

The dust concentration in the pipeline should not be higher than 200g/m³ |

|||

Technical Parameters Specifications

|

Product Specifications |

Flange inner diameter d(mm) |

Flange outer diameter D(mm) |

Hole center distance φK(mm) |

Flange hole n-φL |

Length L(mm) |

Width W(mm) |

Height H(mm) |

|

BD-FT2RZ-150 |

150 |

250 |

210 |

8-14 |

450 |

350 |

300 |

|

BD-FT2RZ-200 |

200 |

300 |

260 |

8-14 |

500 |

400 |

350 |

|

BD-FT2RZ-300 |

300 |

400 |

360 |

12-14 |

600 |

500 |

450 |

|

BD-FT2RZ-400 |

400 |

500 |

460 |

16-14 |

700 |

600 |

550 |

|

BD-FT2RZ-500 |

500 |

600 |

560 |

20-14 |

800 |

700 |

650 |

|

BD-FT2RZ-600 |

600 |

700 |

660 |

24-14 |

900 |

800 |

750 |

|

BD-FT2RZ-700 |

700 |

800 |

760 |

28-14 |

1000 |

900 |

850 |

|

BD-FT2RZ-800 |

800 |

900 |

860 |

32-14 |

1100 |

1000 |

950 |

|

BD-FT2RZ-900 |

900 |

1000 |

960 |

36-14 |

1200 |

1100 |

1050 |

|

BD-FT2RZ-1000 |

1000 |

1100 |

1060 |

40-14 |

1300 |

1200 |

1150 |

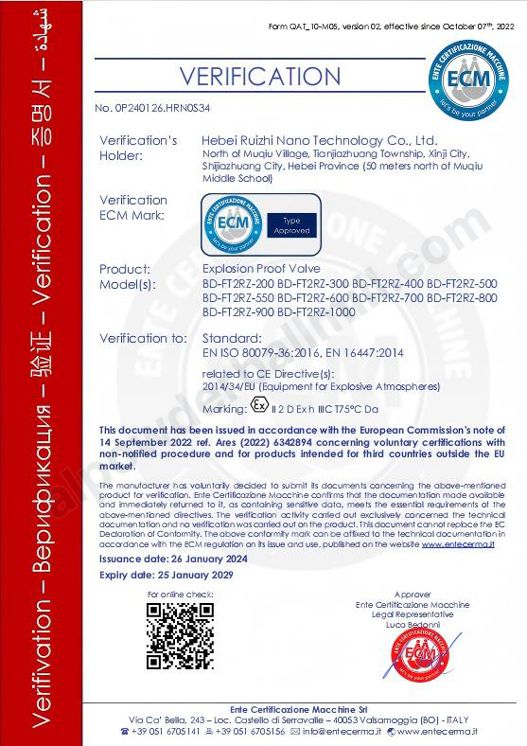

CE Certified

FAQ

Q1 What qualifications and certifications does your company have?

Our company is ISO9001:2015 certified, with CE certified dust explosion-proof equipment. Some products comply with EN standards. Ruizhi is also a member of the Fire and Explosion Prevention Working Group of the National Committee for Machinery Safety Standardization.

Q2 Is there independent intellectual property rights and third-party testing?

Yes. We own several patents in explosion-proof systems and can provide third-party test reports such as CNAS and CE.

Q3 How long is the delivery cycle?

Standard equipment delivery is 5–9 weeks. Spare parts are usually in stock for fast shipping.

Q4 How to ensure packaging and transportation?

All products are packed in moisture-proof, anti-static, shock-resistant wooden cases, suitable for sea and air shipping.

Q5 How long is the warranty period?

We provide remote support, and operator training through manuals and video tutorials.

Service Warranty

Work with Ruizhi – Global Dust Safety Partner

News Center

Hebei Ruizhi Nano technology Co., Ltd.--30 years of innovation in explosion-proof milling and dust safety equipment, trusted by industries worldwide.

Nov. 26, 2025

Hebei Ruizhi Pioneers Explosion-Proof Grinding Technology in Global Industrial Safety Field

Nov. 24, 2025

Nov. 24, 2025

About Us

With 30 years of experience and 90% market share in China’s aluminum powder explosion-proof systems, Ruizhi provides safe, certified, and efficient solutions for industries worldwide.

Navigation

Navigation

Contact Information