Nov 24, 2025

In September 2025, the 23rd China International Coatings Exhibition grandly kicked off at the Shanghai New International Expo Center. Hebei Ruizhi Nano Technology Co., Ltd. (hereinafter referred to as "Hebei Ruizhi") participated in the exhibition with its independently developed powder explosion-proof grading grinding system and series of professional accessories. With the technical concept of "making powder manufacturing safer", it attracted widespread attention from the industry.

Explosion proof technology leads industry safety upgrade

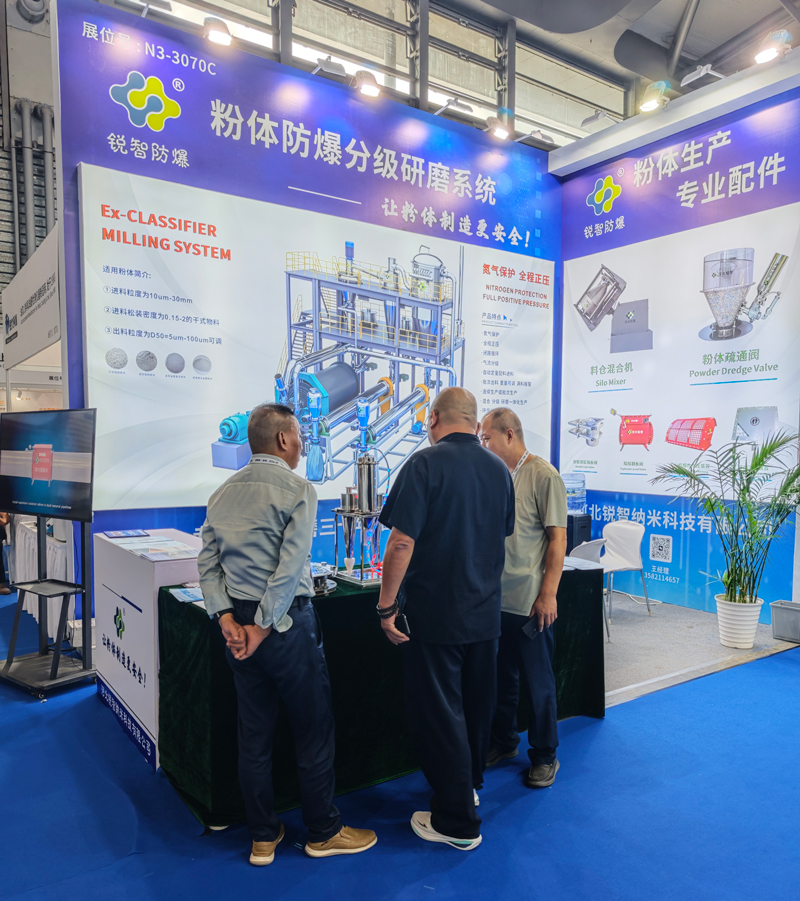

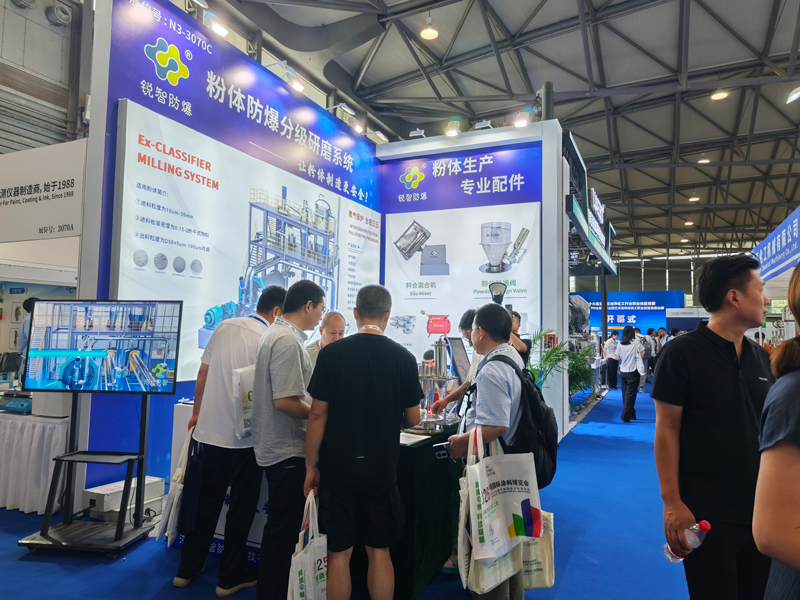

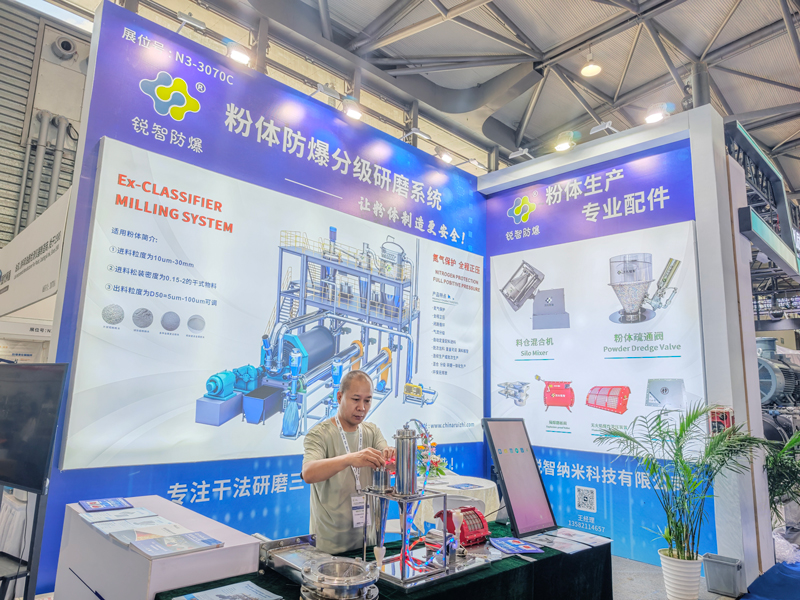

At the exhibition site, the booth of Hebei Ruizhi located at N3-3070C was crowded with people. The core exhibit, the powder explosion-proof grading grinding system, became the center of attention with its innovative design of "nitrogen protection and full process positive pressure". This system targets the safety pain points that are prone to explosions in powder processing, and achieves full process explosion-proof control from raw material input to finished product output through technologies such as inert gas environment construction and precise grading and grinding.

According to on-site technicians, this system can handle dry materials with a feed particle size of 10 μ m-30mm and a loose density of 0.15-2g/cm ³. The discharge particle size D50 can be flexibly adjusted between 5 μ m-100 μ m, which not only meets the needs of industries such as coatings and pigments for fine powder processing, but also eliminates the risk of dust explosion from the root, building a "safety firewall" for the powder manufacturing process.

Full category accessory solutions highly recognized

In addition to the core grinding system, the powder production professional accessories exhibited by Hebei Ruizhi are also highly anticipated. Products such as silo mixer, powder dredging valve, and flameless explosion-proof device cover the entire process of powder production from mixing, transportation to safe discharge.

At the booth, the staff demonstrated the working principle of the powder dredging valve on site - this accessory can efficiently solve the bridging and blocking problems during powder transportation, and together with the explosion-proof grinding system, form a dual guarantee of "safety+efficiency". Many representatives of coating production companies attending the exhibition expressed that this "one-stop" powder equipment and accessory solution greatly simplifies the supply chain procurement process and is more in line with the actual needs of industrial production.

Empowered by technology, exploring new paths for industry security development together

During the exhibition, the technical team of Hebei Ruizhi had in-depth exchanges with professional visitors from the fields of coatings, inks, new materials, etc., to explain in detail the application scenarios of powder explosion-proof technology in coating production. The coating industry has extremely high requirements for the purity and particle size distribution of powder raw materials, and traditional processing methods are prone to safety hazards. However, our system can achieve precise grading and efficient grinding of powders while ensuring safety, "said Manager Wang, the on-site manager.

This exhibition not only showcased Hebei Ruizhi's technological strength, but also conveyed the industry development concept of "safety first". In the future, the company will continue to deeply cultivate the field of powder explosion prevention, promote the safety production upgrade of coatings and related industries with innovative technologies, and inject more impetus into the high-quality development of the industry.

Work with Ruizhi – Global Dust Safety Partner

About Us

With 30 years of experience and 90% market share in China’s aluminum powder explosion-proof systems, Ruizhi provides safe, certified, and efficient solutions for industries worldwide.

Navigation

Navigation

Contact Information